The company has gained ISO9001 quality system certificate. The quality systematic files include quality manual, program files, operation instructions. The company has issued a complete set of inside-control regulations to make sure the quality system running effectively.

The company strictly carried out the quality policy of "Quality First, Scientific Management, Clients superior and Service superior" to organize production and service. In order to reach the quality object, the company takes the guarantee and improvement of product quality as priority. In case that any negative affection to the product quality occurs, the correcting measures should be taken to handle immediately. Meanwhile, the company has introduced the world advanced management methods and absorbed superior talents, thus the management of the company ultimately has been improved and a sustainable product quality, the company has established a set of perfect program files and operating instructions about the entirely process from materials purchase to production and installation, controlling from the upstream, monitoring the entry of raw materials strictly and strengthening the quality control to eliminate the possible hidden quality problems.

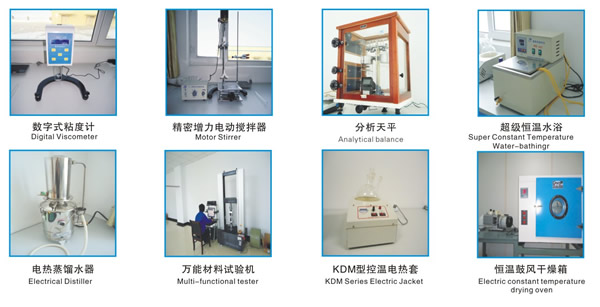

1、Advanced equipment of production and test.

The company introduced a complete set of pipe's production and test equipment. the products can be controlled by the computer from the process of design to forming.

The reality and reliability of the products quality can be assured according to the Advanced production equipment, test equipment and scientific test method provide.

2、Abundant technology strength

The company has cooperated with domestic and overseas famous science researching institute,

universities and colleges to together research and develop new technologies and new products since its established and engaged some experts,

professors as technology consultant for the company thus effectively guarantee the company's technologies and products quality can be increased continuously.

3、Scientific production management

We made the inspection during in all production process and strictly control the entry of materials, quality on every working procedures and change the inspection after it happened to prevention before it happen.

4、Correction and prevention measures

The company specially established the quality team that combined various people from different department and this team can analyze,

research the quality problem that happened from the entry of raw materials to installation and provide effective correction and prevention measures in time.

The quality problem would be solved by the PDCA method so that assure the products quality.